At Steadfast, LLC, we love new construction technology. We can’t wait to share information about the newest materials and gadgets that will keep your staff safer, make your projects go faster, help the environment, and make you money. And while they might not be as much fun as drones or concrete made from lunar dust, data collection apps can do all those things and more.

What are Data Collection Applications?

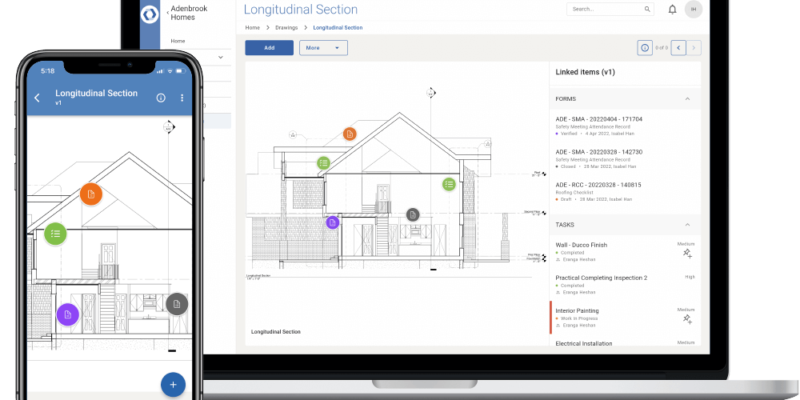

Put in the simplest terms, data collection apps are mobile programs that collect and store information about your project before, during, and after the job.

Construction teams have been collecting data for years (think blueprints, the types and amounts of materials they would need, incident reports, etc.), but up until recently that data was kept on paper. While paper has served us well, it did come with some problems, like being easily damaged (hello, coffee stains), bulky, time consuming, and prone to error.

It’s no surprise, then, that computer engineers started working on data collection software as early as the 1980s. Thanks to the cloud, this software has become one of the most widely-used technologies on construction sites today.

All kinds of useful data can be collected via these applications: they take and share pictures, GPS locations, signatures, and more. You can pull up plans, forms, schedules, and other documents without having to carry around bulky paperwork. And most allow you to store data offline, so they can still be used in areas without reliable internet.

How can they help you?

If you already have a paper system, it might be tempting to not change something that’s not broken. Just because something is functional, however, doesn’t mean there isn’t a much, much better way. These data collection apps are so effective, even the most traditional site managers are making the switch. You can’t argue with the many financial and safety benefits!

1. Saving Time

How would you feel about having 20 hours back in your week?

That’s how many administrative and field hours that app users report saving, thanks to increased efficiency. Since the software reduces data entry errors, you aren’t spending time correcting mistakes or hunting down missing signatures.

GPS allows staff to easily find the exact site where a fix is needed, and you can easily send pictures and videos so everyone doesn’t have to drive to the site. And this improved workflow has one bottom line: jobs are finished in record time, meaning you’re making money faster.

2. Keeping Workers Safe

You want to keep your workers safe. Yet most workers avoid completing lengthy or complicated forms when they can, so many near-miss accidents or inspections get skipped. By making them accessible digitally, your team can quickly get through daily equipment inspections, easily complete near-miss reporting, and immediately access job safety analysis.

3. Reporting Instantly

The improved workflows brought to your team through data collection apps mean you can do your daily job reports, send client deliverables, and access legal documents right from your phone or tablet at your jobsite. Clear results and the ability to make instant decisions will help you have more accurate and dynamic control of every project.

Which one should we use?

As data collection continues to improve, more apps are becoming available every day with a wide variety of user friendliness and prices. When considering which one to use, there are some important factors to consider.

First, what devices will you be using? Many apps are specific to iOS (iPhones), android, or web technology. Next, what type of internet access do you have? If you are regularly working on jobs in areas with little to no internet access, you’ll want to make sure the app you choose has several offline options. Finally, will you be taking measurements one time or repeatedly? All of these factors, along with price point, will go into figuring out which app will work best for you.

Explore a list of some of the most popular apps here.

At Steadfast, LLC, we’re committed to helping you find the best staff, equipment, and technology to help you complete your jobs safely and efficiently. Contact us today to find out how we can help you get the job done right: jhworthy@steadfastentities.com.