Summer brings longer days and ideal conditions for construction projects, but in many parts of the country it can also present significant health and safety challenges for workers.

High temperatures, intense sunlight, and the physical demands of construction work can pose serious risks for workers who aren’t prepared. Since employee safety is the number one priority for us here at Steadfast, we’ve put together some strategies construction companies can implement to protect their employees during these next hot summer months.

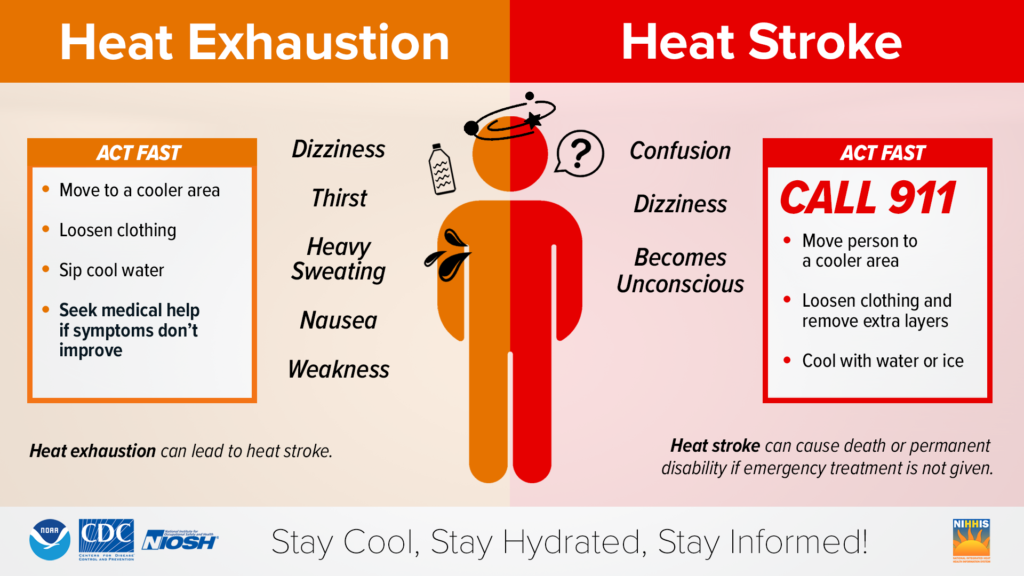

Educate Employees on Heat-Related Illnesses

Knowledge is power, and understanding the symptoms and dangers of heat-related illnesses like heat exhaustion and heatstroke, is crucial to employee safety. Conduct regular training sessions to educate workers on how to recognize these conditions, the importance of hydration, and the steps to take if they or a coworker start experiencing symptoms.

Implement a Heat Safety Plan

A comprehensive heat safety plan should include guidelines for work-rest cycles, hydration, and monitoring weather conditions. Schedule the most strenuous tasks during the cooler parts of the day, typically early morning or late afternoon. Ensure that workers take regular breaks in shaded or air-conditioned areas, and encourage employees to look out for one another.

Provide Adequate Hydration

Dehydration is a major risk during the summer, so make sure you provide your team with plenty of water and encourage them to drink small amounts frequently (rather than just waiting until they feel thirsty). Electrolyte-replenishing beverages can also help maintain the body’s salt balance. Providing coolers of both are a low-cost way to help encourage workers to get the hydration they need.

Create Shaded and Cool Rest Areas

Designate shaded areas where workers can rest and cool down, and make sure they are using them as needed. If natural shade isn’t available, consider setting up tents, canopies, or portable cooling stations. Cooling towels and misting fans can also provide relief.

Use Protective Clothing and Gear

Encourage workers to wear lightweight, light-colored, and loose-fitting clothing to reflect heat and promote ventilation. Hats, sunglasses, and sunscreen with a high SPF can protect against harmful UV rays. Provide personal protective equipment (PPE) that is designed for hot weather, such as ventilated helmets and moisture-wicking fabrics.

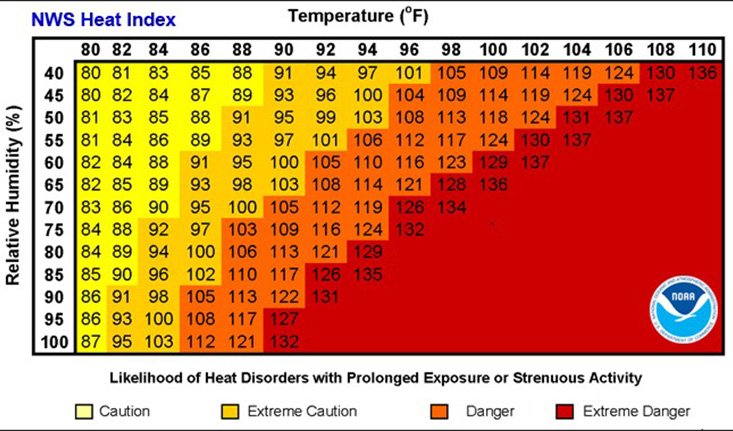

Monitor Weather Conditions

Keep a close eye on weather forecasts and heat advisories. Adjust work schedules and plans according to the predicted temperatures and humidity levels. Consider using heat index charts to determine safe working conditions and adjust activities accordingly.

Acclimatize Workers

New and returning workers may need time to adjust to the heat. Implement an acclimatization plan that gradually increases exposure to high temperatures over a week or two. This helps the body adapt to the heat, reducing the risk of heat-related illnesses.

Promote a Culture of Safety

Foster an environment where safety is prioritized. Encourage workers to look out for each other and to report any safety concerns. Regularly review and update safety protocols to ensure they remain effective and relevant.

Use Technology

Where possible, leverage technology to monitor worker’s health and safety. There are a wide range of wearable devices that can track vital signs and detect early signs of heat stress. There are also a wide variety of apps and software that can provide real-time updates on weather conditions and send reminders for hydration and breaks.

Emergency Preparedness

Ensure that all workers are trained in first aid and know the procedures for dealing with heat-related emergencies. Keep first aid kits readily available and equip supervisors with the tools and knowledge to respond quickly to any incidents.

Protecting your team from the dangers of summer heat requires a proactive and comprehensive approach. By educating employees, providing adequate resources, and fostering a culture of safety, construction companies can create a safer work environment and maintain productivity throughout the summer months. Implementing these strategies not only safeguards the health and well-being of workers but also demonstrates a commitment to their safety and job satisfaction.