The construction industry often struggles with diversity.

It’s most clear when it comes to gender: as of 2021, women comprise only about 8% of the total construction workforce, despite making up 47% of all employed people worldwide. Of that 8%, only about 1% work on jobsites, with the majority of women being placed in office and sales positions.

Similarly, there is a huge disparity when it comes to race: 58.7% of those working in construction are white, followed by 24.5% Hispanic or Latino and 10.7% Black or African American.

Why does it matter?

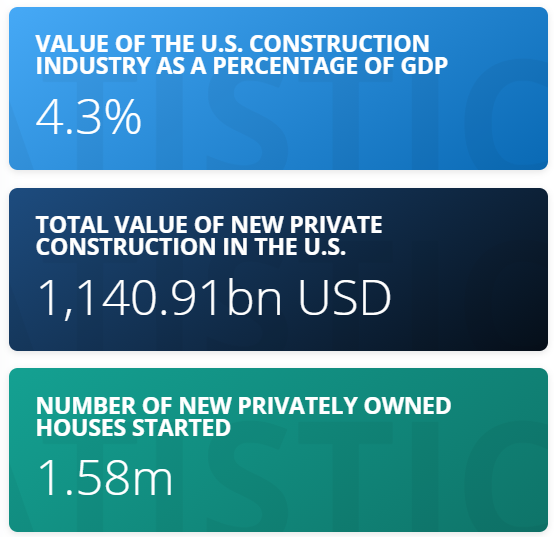

Research has shown that having a wider mix of people on your staff improves morale and productivity, and keeps workers on your team longer. The good news is that diversity is always improving and there are things you or your job leaders can do to help. With the ever-increasing housing market, it’s expected that the industry will need another 430,000 workers in the coming year. Widening your search to include underrepresented individuals can help fill those labor gaps. This also tends to improve performance, as a larger hiring pool means opening yourself up to finding more talent and a wider range of skills (studies have shown inclusive firms have 1.32 times higher productivity than less diverse firms).

An increase in talent can also lead to improved problem-solving, as a wide range of experiences and perspectives mean more innovation when facing challenges on the jobsite. More innovation leads to quicker solutions, which means your company can outperform your less diverse competition. It’s also going to get you noticed, as high performance and a positive work environment are two of the best ways (along with decent pay and benefits) to attract and retain quality craftspeople to your team – critically important with today’s labor shortages.

How do I diversify my workforce?

First, check in with yourself. Make sure that you are offering the same opportunities for leadership and promotion to everyone. For example, are the women on your team offered the same leadership opportunities as the men, or are they limited to only administrative positions? These changes often start with company management reevaluating their current policies, and making sure they are free from unconscious biases and discrimination. This could mean changing promotion criteria and providing diversity training to both management and employees.

When hiring new employees, aim for a blind review that omits the applicant’s name so you can be more impartial. Have multiple people on your hiring team, and whenever possible include people from diverse backgrounds.

Building new partnerships is also key to bringing in new and varied talent. Starting a partnership with a local high school, community college, or nonprofit to teach youth and young adults construction skills can not only get your name out into the community, but can also jump start the training of your next batch of employees with little effort on your part. This also ensures the diversity of your workforce is representative of your community.

Diversity and inclusion is the way of the future. Put your organization in a position to succeed by hiring and promoting a diverse range of staff. With this mindset, you can resolve labor shortages while ensuring your staff feel safe, satisfied, and empowered in the new year.