Steadfast has seen exciting growth in the area of Geographic Information System (GIS) mapping. This technology is used to enhance project management, efficiency, and accuracy throughout construction.

By integrating GIS into construction processes, companies can visualize, analyze, and interpret spatial data to make informed decisions. This post explores GIS and how its integration is revolutionizing the construction industry.

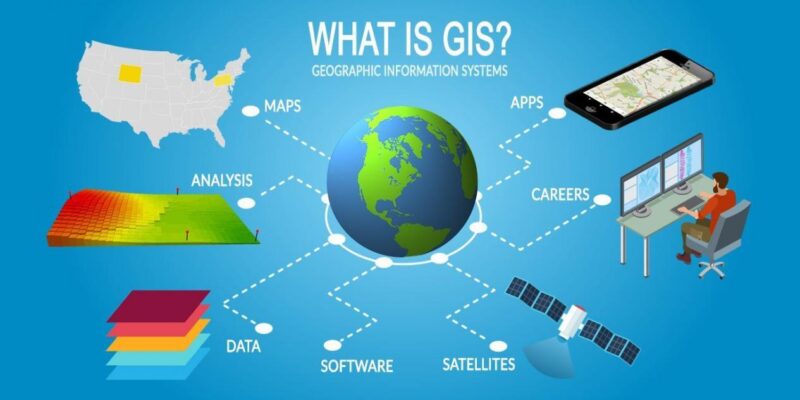

What is GIS?

GIS mapping is a technology that captures, stores, analyzes, and displays geographically referenced information. Essentially, GIS combines layers of data linked to specific locations on the Earth’s surface, creating detailed maps and models. These maps can include various types of information, such as topography, infrastructure, land use, environmental data, and more.

How GIS is Being Used in the Construction Industry

Site Selection and Planning

GIS allows construction companies to conduct detailed site analyses, considering factors such as soil type, topography, vegetation, and proximity to utilities. By overlaying multiple data layers, companies can identify the most suitable locations for their construction projects, ensuring that the chosen site meets all necessary criteria for safety, accessibility, and environmental impact.

Design and Visualization

Using GIS, architects and engineers can create detailed 3D models of construction projects. These models provide a visual representation of how a project will look once they’re completed, helping stakeholders understand the scope and scale of each project. This visualization aids in identifying potential design flaws and making necessary adjustments before construction begins.

Infrastructure Management

GIS is instrumental in both managing existing infrastructure and planning new developments. It allows for the mapping and monitoring of utilities such as water, electricity, and sewage systems. This ensures new construction projects do not interfere with existing infrastructure and improves planning efficiency.

Environmental Impact Assessment

With sustainability being top of mind for many investors, environmental considerations are also important for most modern construction projects. GIS helps in assessing the environmental impact of construction activities by mapping sensitive areas such as wetlands, forests, and wildlife habitats. This information can then be used for obtaining necessary permits and ensuring compliance with environmental regulations.

Project Management and Monitoring

GIS provides construction managers with tools to monitor project progress in real-time. By integrating GIS with other project management software, managers can track the movement of equipment, materials, and personnel. This real-time data helps managers make informed decisions, optimizing resource allocation and keeping projects on schedule.

Disaster Risk Management

Construction projects must also account for potential natural disasters such as floods, earthquakes, and landslides. GIS aids in mapping hazard zones and assessing the risk levels of different sites. This information is crucial for designing buildings that can withstand such events, and for creating emergency response plans that can ultimately save lives by being prepared for the worst.

Community Engagement

Engaging with the local community is an important aspect of many construction projects. GIS maps can be used to present project plans to the public, providing a clear and understandable visualization of the project’s impact on the community. This transparency helps in gaining public support and addressing any concerns that may arise.

Case Study: GIS in Action

One notable example of GIS integration is the construction of smart cities.

In these projects, GIS is used to plan and manage urban infrastructure, ensuring that transportation, utilities, and public services are optimally designed and efficiently operated. By leveraging GIS technology, smart city projects can improve quality of life, reduce environmental impact, and create more sustainable urban environments.

Check out our previous blog post about SMART infrastructure, and how it is changing the future of construction.

The integration of GIS mapping in the construction industry is transforming how projects are planned, managed, and executed. From site selection to environmental impact assessments and real-time project monitoring, GIS provides invaluable insights that enhance efficiency, accuracy, and sustainability. As the construction industry continues to evolve, we can’t wait to see how the adoption of GIS technology will continue to play a pivotal role in shaping the future of construction.

Embracing GIS not only leads to better project outcomes but also demonstrates a commitment to innovation and responsible development. At Steadfast Entities, LLC, we pride ourselves on that same commitment by offering state of the art equipment and highly trained staff for all of your construction needs. Contact us today to find out how we can make your next project your best yet!