The only difference between men and boys is the cost of their toys.

Anonymous

Let’s face it: we’re all just kids having fun with our toys.

Ask any little boy (and many girls!) between 4 and 8 years old what they want for Christmas, and odds are most of them will tell you a truck, crane, or some other small version of machinery.

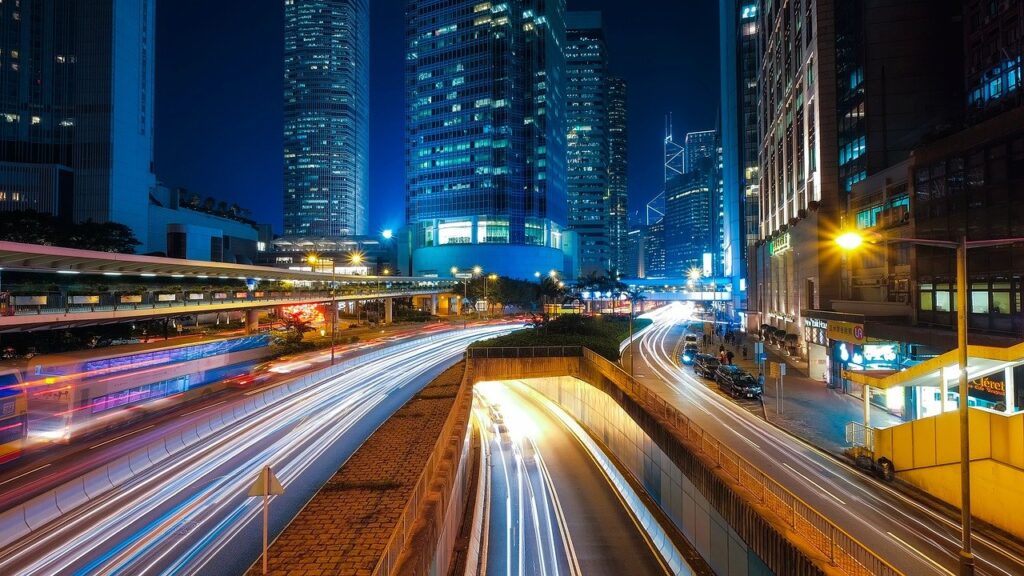

There’s a love there that we all share, something magical about operating a mechanical device to move earth, crush garbage, and do things we could never do on our own. Modern machinery allows us to make the impossible happen, giving the operator a sense of wonder and control at the same time.

While technology keeps progressing, giving us newer and more interesting devices to play with, children also reap the benefits:

CleverLeverage listed many machines that are available in kid sizes, including excavators and diggers with backhoe attachments! Diggerland Theme Park also gives kids (and adults) the opportunity to use life-size machinery to crush and carry.

There’s a reason both children and adults get a kick out of operating machinery and exploring the possibilities of new tech: we love playing.

For many of us in the heavy equipment and construction fields, operating heavy equipment, playing with new gadgets, and exploring the cool things we can do with new technology is all part of the same childhood love.

At Steadfast Entities, we’re so lucky to keep playing with the things we love! Specializing in heavy equipment and modern construction technology, the opportunity to learn, explore, dig, crush, and move never ends.

This curiosity is so important, as technology is constantly defining the construction industry and moving us forward. Learning new and better ways of creating our world will carry us into the future. Explore some of the cool tech that Steadfast Entities has available here!