3D printing has been around since the early 1980s, but over the last few years it has ballooned into one of the fastest growing construction technologies on the market. Its versatility, efficiency, and economy make it a useful tool in every step of the construction process.

How Does It Work?

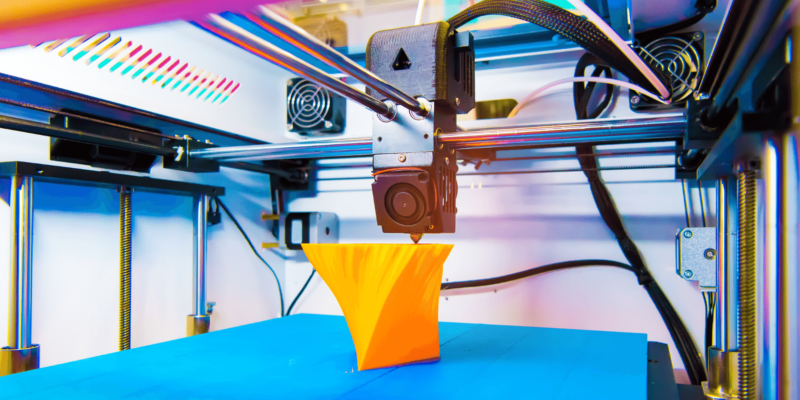

To create a 3D print, a CAD or BIM program sends the required information to the printer, which then prints the object in layers. While these layers can be many different types of materials, the most common used in construction is a mixture of concrete, sand, fiber, and geo polymers.

SQ4D, an Australian construction company, has built an industrial sized 3D printer that they can use to build housing on any lot. You can watch a video of the building and see the finished home here.

Why 3D Printing?

Thanks to the CAD or BIM programming we mentioned before, builders using 3D printers know the exact amount of material they need for the project. This cuts down on waste at the jobsite, as well as the cost of surplus materials and their storage, making 3D printing more sustainable and cost effective. On average, 3D printed projects generate 60% less waste.

3D printing also saves time, with 3D printing going approximately 70% faster than traditional builds. This time saving allows companies to start and complete more projects, which increases both profits and, if building housing, the number of living spaces readily available on the market.

Finally, since 3D printing works autonomously, it requires fewer laborers on the jobsite (most companies that switched to 3D printing saw an 80% decrease in labor costs). Since the construction industry has been hard hit by labor shortages across the country, this both saves companies recruiting money and allows them to complete projects on time with far fewer staff. The projects are also much safer for workers, with a substantial reduction in construction injuries when workers have been trained to use 3D printers.

Ongoing Challenges

While 3D printing has a wide range of benefits, there are still some disadvantages. The printers, especially those large enough to be used on construction projects, are incredibly expensive, and can be a challenging upfront cost for new companies. With so few printers being used in the industry, there’s a high need for fully-trained operators who can design the computer models, operate the printers, and provide the required maintenance.

3D printed projects are also limited by the formula of the mixture they print. The mixture has to exit a nozzle, retain its shape, and have a ‘goldilocks’ dry time: too slow and it can’t be layered, too fast and it will hinder the building process.

Despite the constraints, the increased flexibility, efficiency, and safety of 3D printing means it is a growing tool in the construction world and expected to be a $680 million industry by 2030. As construction professionals dedicated to both sustainability and using the most cutting-edge technology, you can count on Steadfast, LLC to keep a close eye on the evolution of this technology!